Machining, Fabrication and Inspection of Empennage Final Assembly Jig

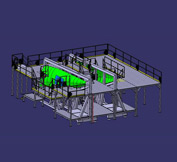

West Cobb Engineering And Tool Inc. is at the forefront of aerospace tool design, and one of our specialties is fabricating large aircraft assembly fixtures, such as the one pictured here. Used for securing the major components and modules for accurate, true, and square assembly of the fuselage of a large transport plane, precision quality construction was critical to achieving the unforgivingly tight tolerance requirement of the aircraft assembly operation.

Using multidisciplinary engineering software gave us a full spectrum of tools for designing an ergonomic and productivity-enhancing solution for this complex assembly structure. Featuring overall dimensions of 28.5′ in length, 6.5′ in width, and 14.0′ in height, we constructed it from steel and aluminum tubing and applied MIG welding techniques to produce deeply penetrating defect-free joints. We utilized a laser tracking system to measure the spatial geometry with pinpoint precision and resolution to verify the dimensional positional accuracy of ± 0.005″.

Our engineers and programmers have been involved with many aircraft projects, and our integrated approach to this design and build project enabled us to meet our commitment to the customer in terms of cost, schedule, and technical performance.If you are interested in learning more, Contact us today.

Empennage Final Assembly Jig Project Highlights

- Product Name

-

Aft Fuselage Assembly Jig

- Capabilities Applied/Processes

-

Primary:

CNC 5-Axis Machining

Welding

Laser Tracker

Jig and FixtureSecondary:

Painting

Stenciling

- Equipment Used to Manufacture Part

-

SNK 250 CNC Machine, MIG Welder, Leica Laser Tracker

- Overall Part Dimensions

-

Length: 28.5 ft.

Width: 6.5 ft.Height: 14 ft.

Estimated Part Weight: 5000lbs

- Tightest Tolerances

-

± 0.005″

- Material Used

-

10″x 10″ and 8″x8-¼” Steel Tubing and Aluminum

- Material Finish

-

Epoxy Painted

- In process testing/inspection performed

-

Dimensional Inspection, Visual Inspection and use of Leica Laser tracker for setting details on jig.

- Industry for Use

-

Aerospace – Large Transport Aircraft

- Delivery/Turnaround Time

-

20 weeks

- Standards Met

-

Customer Specifications, 2D CAD Drawing, CATIA Electronic Model

AS9100 REV D

ISO 9001:2015